20kg ho isa ho 50kg Mochini o Bula oa Molomo oa Mokotla bakeng sa Poone e Broken, Poone Flour, Fine Corn Flour, Poone

Lintlha

Tlhaloso ea tekheniki

| Lebitso | Mochini o bulehileng oa ho roala mekotla |

| Boima ba mekotla | 20-50kg |

| Lebelo la ho paka | 6-12mekotla/metsotso |

| Thepa ea Mokotla | Bophara: 400-520mm;bolelele: 550-950mm |

| Tšebeliso ea moea | 1Mpa |

| Tšebeliso ea khase | 2m³/min |

| Matla a matla | 220VAC/380 mekhahlelo e meraro/50HZ |

| Matla | 8kw |

kopo

| Granule | Peo, peanut, linaoa tse tala, pistachio, tsoekere e hloekisitsoeng, tsoekere e sootho, lijo tsa PET, Polyester Chipslitlolo tsa polyester,lijo tsa liphoofolo, lijo tsa aqua, lijo-thollo, moriana oa granular, capsule, peo, li-condiments, tsoekere e nang le granulated, motsoako oa khoho, peo ea mahapu, linate, li-granules tsa manyolo joalo-joalo. |

| Phofo | phofo ea lebese, phofo ea kofi, li-additives tsa lijo, li-condiments, phofo ea tapioca, phofo ea kokonate, phofo e bolaeang likokoanyana, phofo ea lik'hemik'hale joalo-joalo. |

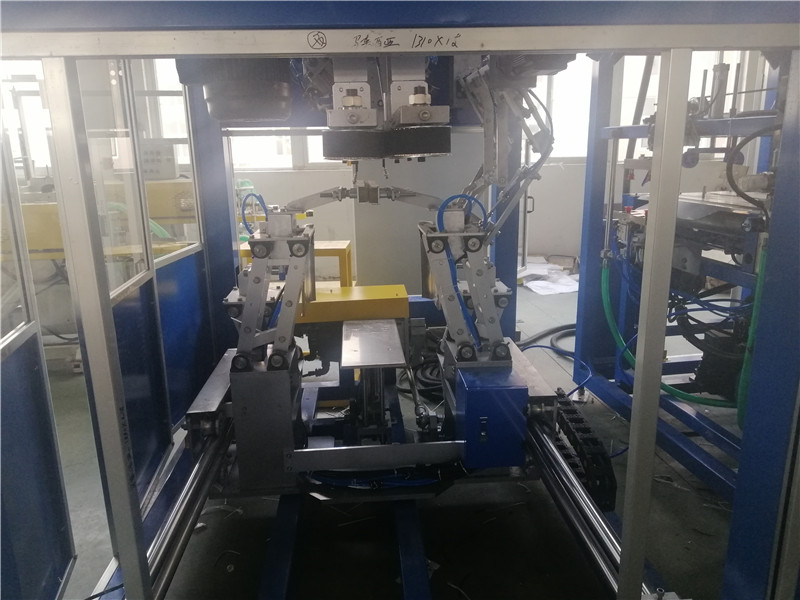

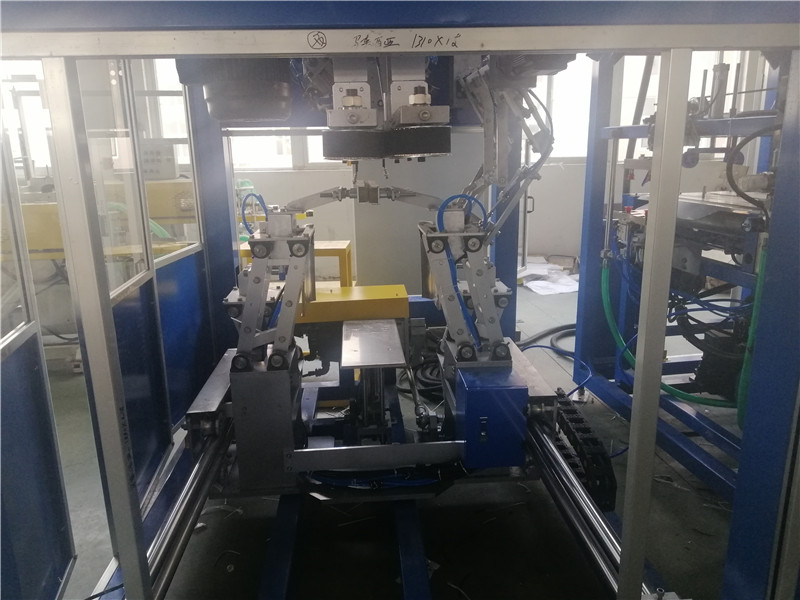

Mehaho e Meholo

1. Auto mokotla beha

2. Sistimi ea ho tlatsa ka boits'oaro (sephepelo sa lebanta)

3. Auto weighting balance

4. Auto mokotla tlatsoa

5. Mokotla oa likoloi o tiisitsoe

6. Khabinete ea taolo ea motlakase

Molemo

1. Dual Hopper Weighing System-- e nang le Mettler Toledo Brand Load Cell

2. Sebelisa likarolo tsa motlakase tsa mofuta oa France Schneider

3. Sebelisa likarolo tsa moea tsa Taiwan kapa Japane kapa Jeremane

4. Fana ka bophelo bohle ba inthaneteng ka mor'a tšebeletso ea thekiso

5. Mochine o entsoeng le ho etsoa ho latela lilemo tsa 8 + bophelo.

6. Mofuta o itirisang ka botlalo, ha o hloke mosebetsi

Kenyelletso e felletseng ea sistimi

1. Sistimi e loketse mekotla ea pampiri, mekotla e lohiloeng, mekotla ea polasetiki le lisebelisoa tse ling tsa ho paka, tse sebelisoang haholo indastering ea lik'hemik'hale, fepa, lijo, manyolo le liindasteri tse ling.

2. E ka ba e loketseng bakeng sa ho paka mokotla oa 20-50kg, ka matla a ho fihlela ho max 1200bags / hora.

3. Sesebelisoa sa mokotla se ikemetseng se ikamahanya le ts'ebetso e tsoelang pele ka lebelo le phahameng.

4. Mekhatlo ea ho bolaoa e na le lisebelisoa tsa taolo le polokeho, ts'ebetso e tsoelang pele e ikemetseng.

5. Ho sebelisa SEW motor drive unite ho ka bapala ts'ebetso e phahameng.

6. Tlhahiso e ts'oanang ea mochine oa ho tiisa mocheso oa KS o sebetsa ho etsa bonnete ba hore mokotla o motle, o khahlanong le ho lutla, o thibela moea.

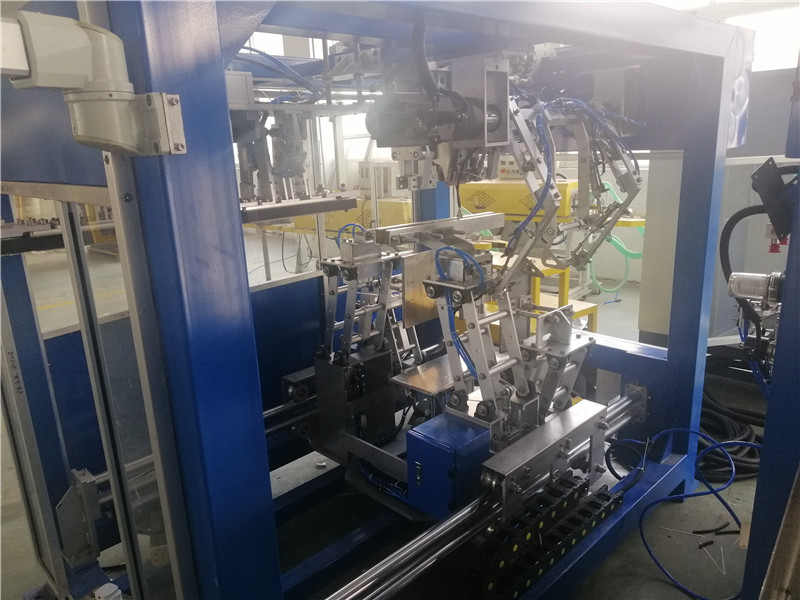

Mokhoa o ikemetseng oa mochini oa ho paka

1. Automatic bakeng sa mekotla-> 2 agned ho rapameng hanyetsang mekotla disk ka boloka hoo e ka bang 200 e se nang letho mekotla( polokelo bokgoni ka lebaka la botenya ba air bag fapana), nka mekotla ho tswa ho monyang senoelo sesebediswa sesebediswa bakeng sa mekotla.Ha mokotla o se nang letho ka mor'a ho nka yuniti, seta terei ea mokotla e latelang e fetoha ka bo eona ho nka boemo ba mokotla ho netefatsa ts'ebetso e tsoelang pele ea sesebelisoa.

2. Mokotla--bit integer-->ho lokisa boemo bohle ba mokotla.

3. Ho ntšoa ha mokotla o se nang letho --> mokotlana oa ho ntša sejana sa polasetiki holim'a mokotla.

4. Lateral movement-->mokotla o se nang letho o tšoaroe ke sekhechana se ka tlase ho mekotla ea 'mele oa spout, o bula lemati ka har'a phepelo ea mokotla.

5. Mokotla o se nang letho o bulehile-->mokotla o se nang letho ka mor'a ho fallela sebakeng sa ho bula phepelo, bula mokotla ka vacuum suction.

6.Mokotla oa ho fepa -> mokotla o se nang letho o ts'oaroe ke sekhechana se ka tlase ho mekotla ea 'mele oa spout, o seha lemati le kenang ka har'a phepelo ea mokotla.

7. Transition hopper + lemati la lisebelisoa tsa bobeli -> hopper bakeng sa karolo ea phetoho pakeng tsa mochine o boima le mechine ea ho paka, mosebetsi o ka sehloohong oa thepa ea bobeli ke monyako o haufi le ts'ebetso e liehang ea ts'ebetso ea thepa ho fokotsa lisebelisoa tsa moea.

8. Ka mor'a hore mokotla o ka tlaase o otle sesebelisoa -> thepa ea ho tlatsa, sena se bolela ho otla ka tlaase ho mokotla, e le hore thepa ea mokotla e kenngoe ka botlalo.

9. Solid lateral movement le mokotla o tšoereng li-inductions tsa mokotla --> mekotla ea sebele ho tloha spout ho kenya li-pouch pouchs conveyor, ka mokotla o tšoereng ho bolela ho tšoara mokotla o fanoeng ho tiisoa.

10. Lipokoana tse emeng->-> mekotla ea 'nete eo ho eona sepalangoang se tsamaeang ka lebelo le sa khaotseng la ho fihla ho theosa le noka, bophahamo---lehatlapa le ka feto-fetohang.

11. Transition conveyor-->le fapaneng sesebediswa bophahamo ba butt phethahetseng.

kopo

Ho paka